Carbon nanotubes (CNTs) are an important class of carbon-based nanomaterials for which numerous applications, particularly in the field of filtration, are being discussed.

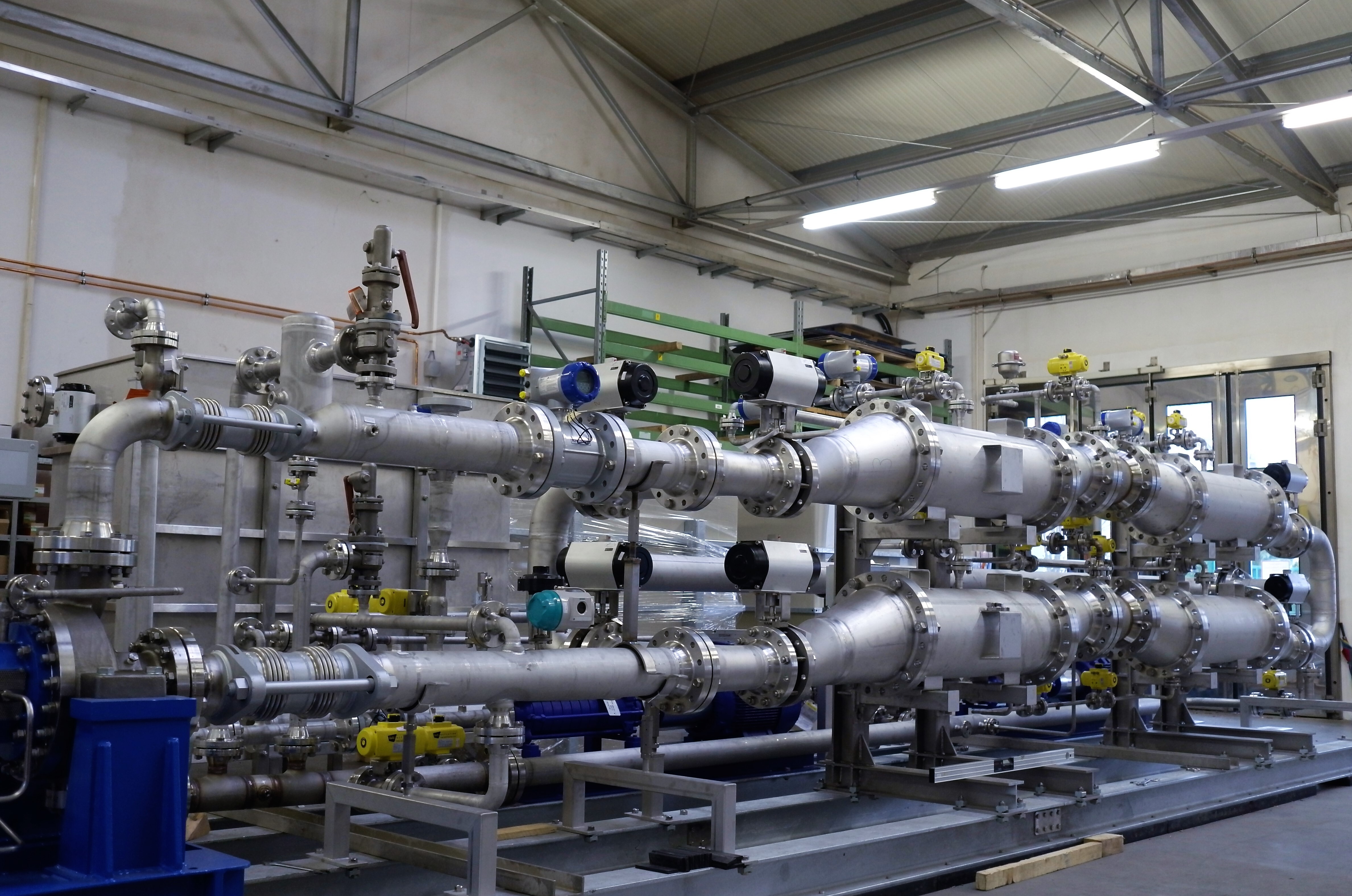

If the project is successfully completed, CNT membranes will be available for the first time that can be used practically which have multiple advantages over conventional membranes and are suitable for the treatment of process water, especially for oil and natural gas production. Consideration of economic, ecological and ecotoxicological aspects during the development phase aims to ensure the sustainable development of the new filtration technology.

In this project, thin-walled ceramic membranes of adapted wettability and high volume specific membrane area are to be developed and tested for the sustainable treatment of mining waste water by means of nanofiltration and membrane distillation.

With regard to turbidity and scaling, the filtration of mining water is associated with a high risk of abrasion and module blocking, which is why the use of ceramic membranes makes sense. At the same time, these are high volume flows, so that large membrane areas are used and inexpensive membranes with a high volume specific membrane area are required.

The consortium covers the entire value-added chain from membrane development to membrane production, process development, plant construction and application.

The research project "Material Toolbox for the Production of High-Performance Ultrafiltration (UF) Membranes for Water Treatment (MABMEM)" focuses on the development of new, high-performance membranes for sustainable raw and wastewater treatment. Under the leadership of BASF SE and with the further participation of its subsidiary company inge watertechnologies GmbH, the chairs of Technical Chemistry and Mechanical Process Engineering / Water Technology at the University of Duisburg-Essen, the research institutes Helmholtz-Zentrum Geesthacht and IWW, and the water suppliers Enwor and OOWV, the project makes a significant contribution to the resource-saving use of water.

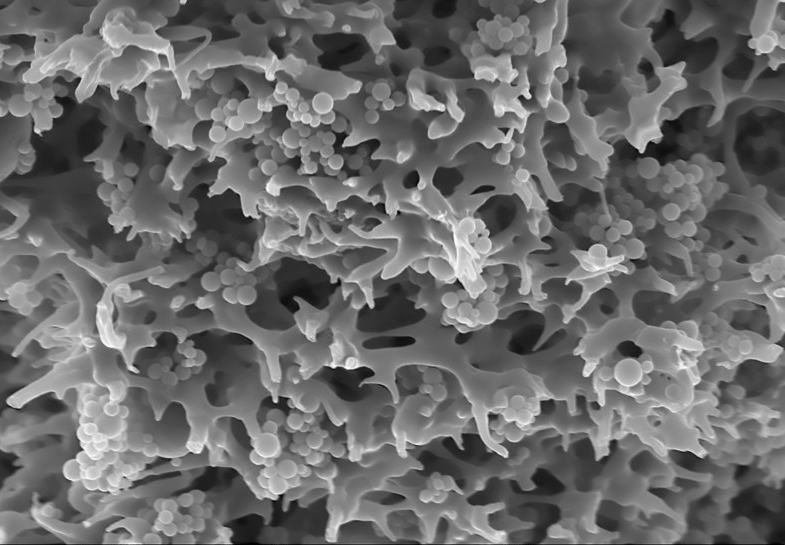

A whole range of different membrane types is already available for water filtration. All of these commercially available membranes use different pore sizes to separate different species by their size. Thereby the porous structure underneath, which offers a high specific surface area, isn´tused. In this project, materials and processes are being developed to fully utilize the space of the membrane for separation. New coating materials and particulate additives are being developed for this purpose. These are either directly integrated into the manufacturing process or integrated into the membrane in apost-treatment step. This approach makes membranes accessible, which can adsorptively bind substances dissolved in water in addition to their filtration function.

The aim of this research project is to produce and test acid-resistant reverse osmosis tubular membrane modules for the treatment of process water containing particles through new coating processes with tailor-made polymeric interface layers. These are applied in booth generative ( layer by layer) and reactive interfacial polymerization. By using polyelectrolytes of different lengths and charges, the separation properties are to be tailored to meet the specific requirements. Acid-resistant tubular membrane modules are developed for process water containing particles from surface treatment. The development will allow the separation of an almost ion-free permeate for water circulation for industrial production in a single process step.

Photo credits: v.o. ©Leibniz-Institut für Polymerforschung Dresden e.V., ©Shell Global Solutions International B.V, ©DECHEMA, ©Fraunhofer IGB, ©atech

innovations GmbH