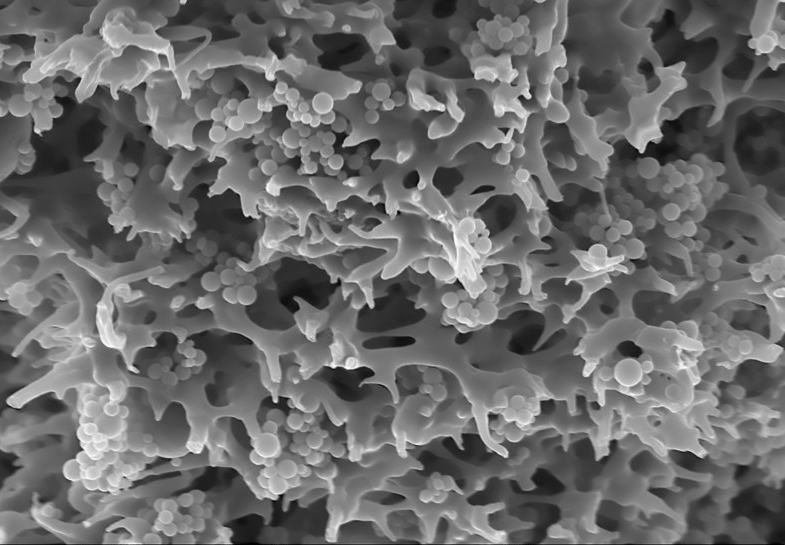

A whole range of different membrane types is already available for water filtration. All of these commercially available membranes use different pore sizes to separate different species by their size. Thereby the porous structure underneath, which offers a high specific surface area, isn´tused. In this project, materials and processes are being developed to fully utilize the space of the membrane for separation. New coating materials and particulate additives are being developed for this purpose. These are either directly integrated into the manufacturing process or integrated into the membrane in apost-treatment step. This approach makes membranes accessible, which can adsorptively bind substances dissolved in water in addition to their filtration function.

Through an innovative integration of functional coatings and surface-modified particles in membranes, mixed matrix membrane adsorbers with multifunctional inner surfaces are being developed that bind different groups of substances with high capacity and selectivity. Then such systems will be transferred to a pilot scale for selected applications and their suitability for real processes will be demonstrated. This approach can be flexibly adapted to changing separation tasks in water management.

In a first step, material libraries for coating and functional particles will be build up in parallel and methods for integrating these materials into membranes will be developed. These developments are then combined in a second step and scaled up to the pilot scale in a third step. Functional tests (separation of micropollutants and heavy metals) are carried out at each development level and the most promising candidates are selected. Finally, demonstrator modules with a membrane separation area of up to 0.5 m² are tested in field tests with real separation problems.

The project consortium consists of the Chair of Technical Chemistry II at the University of Duisburg-Essen, the Fraunhofer Institute for Interfacial Engineering and Biotechnology, as well as the two companies poromembrane and FUMATECH BWT. The partners contribute with complementary know-how to the project.

Dr. Thomas Schiestel

Fraunhofer-Institut für Grenzflächen- und Bioverfahrenstechnik (IGB)

70569 Stuttgart

Universität Duisburg-Essen,

Lehrstuhl für Technische Chemie II

Photo credits: ©Fraunhofer IGB