In this project, thin-walled ceramic membranes of adapted wettability and high volume specific membrane area are to be developed and tested for the sustainable treatment of mining waste water by means of nanofiltration and membrane distillation.

With regard to turbidity and scaling, the filtration of mining water is associated with a high risk of abrasion and module blocking, which is why the use of ceramic membranes makes sense. At the same time, these are high volume flows, so that large membrane areas are used and inexpensive membranes with a high volume specific membrane area are required.

The consortium covers the entire value-added chain from membrane development to membrane production, process development, plant construction and application.

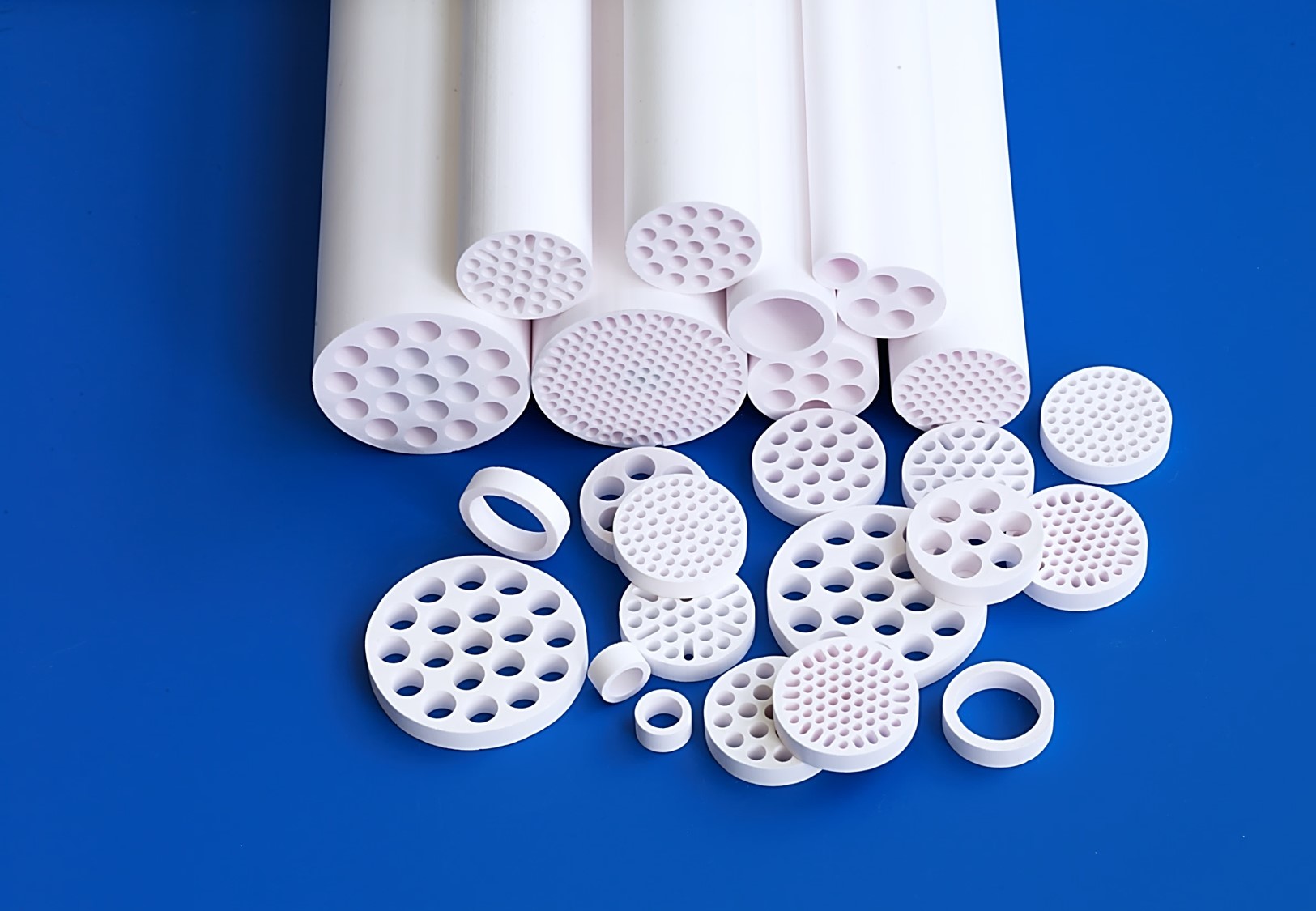

The aim is to develop ceramic membranes made of silicon carbide (SiC) and aluminium oxide (Al2O3) in the form of honeycombs and hollow fibre bundles with hydrophobic macropores for membrane distillation and hydrophilic nanopores for nanofiltration.

The use of porous ceramic honeycombs and hollow fibre bundles considerably reduces the manual handling effort and thus the production costs. However, the narrow, thin-walled, large-volume components and their use in cross-flow filtration and membrane distillation pose high material challenges in terms of design, extrusion, fault-free coating with NF membranes and the targeted adjustment of wettability.

The project KerWas deals with the following areas of work:

Dr.-Ing. Christiane Günther

Rauschert Kloster Veilsdorf GmbH

98669 Veilsdorf

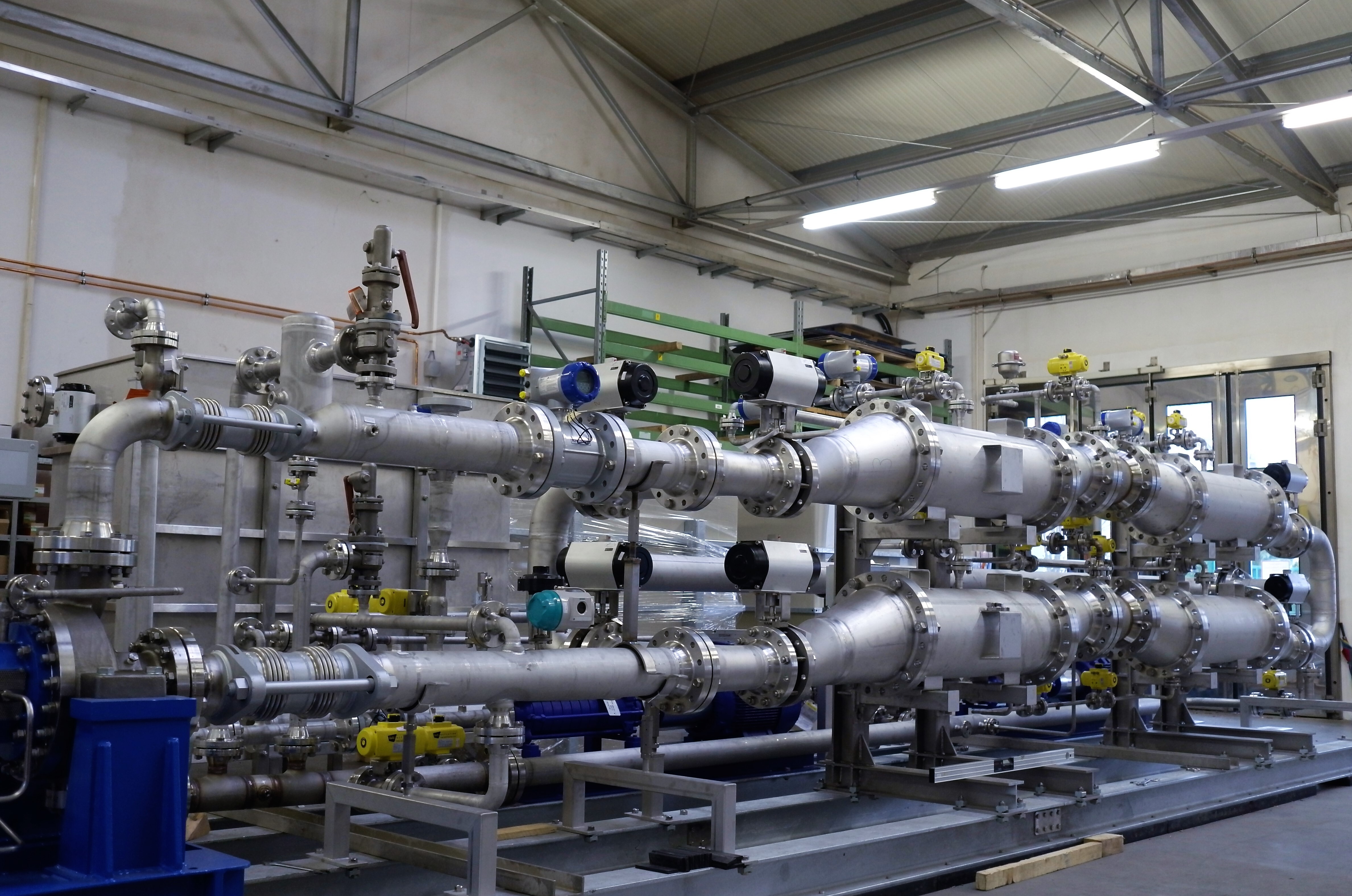

Andreas Junghans - Anlagenbau und Edelstahlbearbeitung GmbH & Co. KG

G.E.O.S. Ingenieurgesellschaft mbH

Fraunhofer Institut für Keramische Technologien und Systeme (IKTS)

TU Bergakademie Freiberg -

Institut für Thermische Verfahrenstechnik, Umwelt- und Naturstoffverfahrenstechnik

Photo credits: oben ©Shell Global Solutions International B.V, unten ©Rauschert Kloster Veilsdorf GmbH